Soldato

Hi all, not been around for a while, hope everyone is doing good.

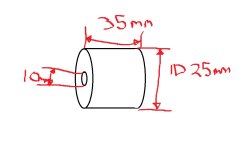

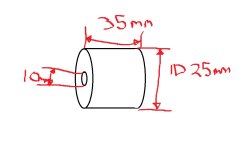

I am in need of a part producing and not sure of the best way to go about it. Its a small pipe with an ID of 25mm and wall thickness around 1.5-2mm, with a 2mm M10 washer fixed to one end, in stainless steel.

Would it be possible to weld it? Would that be a fairly strong join if its welded all the way around? The washer could be over sized, say 35mm or so if that would help strengthen the weld.

Or the best way would be to have it machined, but I'm guessing that would be mega expensive?

Also if anyone knows a decent supplier of stainless pipe for hobbyists that would be awesome. I asked a few sellers on ebay and they want £15 for a 35mm length of 25mm ID stainless pipe, which seems a ripp off. I'd then need to send it to a welder I found on ebay who will weld it for £10 + p&p

I was hoping to find something already made that I could re-purpose, like a railing end cap or similar. I have searched for all sorts, but nothing seems remotely close to what I need.

I am in need of a part producing and not sure of the best way to go about it. Its a small pipe with an ID of 25mm and wall thickness around 1.5-2mm, with a 2mm M10 washer fixed to one end, in stainless steel.

Would it be possible to weld it? Would that be a fairly strong join if its welded all the way around? The washer could be over sized, say 35mm or so if that would help strengthen the weld.

Or the best way would be to have it machined, but I'm guessing that would be mega expensive?

Also if anyone knows a decent supplier of stainless pipe for hobbyists that would be awesome. I asked a few sellers on ebay and they want £15 for a 35mm length of 25mm ID stainless pipe, which seems a ripp off. I'd then need to send it to a welder I found on ebay who will weld it for £10 + p&p

I was hoping to find something already made that I could re-purpose, like a railing end cap or similar. I have searched for all sorts, but nothing seems remotely close to what I need.

So will get that and some washers and see how it goes I think.

So will get that and some washers and see how it goes I think.