Hi all

Just looking for advice.

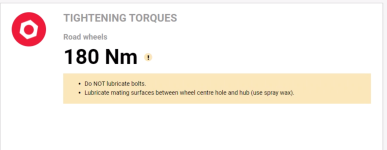

Had some new tyres put on my F11 around 18 months ago, and am now in need of some new tyres. I booked it into a garage a few weeks ago and they were unable to take the wheels off, and actually broke the alloy wheel key trying to get them off. I’ve just had a mobile tyre fitter out who has rounded a bolt and broken one of his sockets trying to get the wheels off.

I guess I’m now looking at having the bolts drilled out? Any idea how much this is likely to cost?

Thanks

Just looking for advice.

Had some new tyres put on my F11 around 18 months ago, and am now in need of some new tyres. I booked it into a garage a few weeks ago and they were unable to take the wheels off, and actually broke the alloy wheel key trying to get them off. I’ve just had a mobile tyre fitter out who has rounded a bolt and broken one of his sockets trying to get the wheels off.

I guess I’m now looking at having the bolts drilled out? Any idea how much this is likely to cost?

Thanks