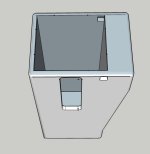

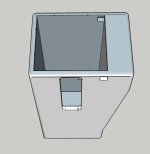

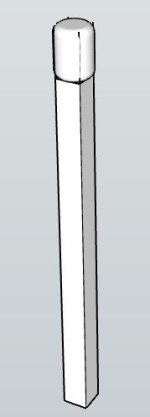

Hi, I wonder if anyone can finish off a design I have done, I would like to make it so the torch can be remove out of the side of the holder, rather then having to remove the holder completely from my chair everytime I want to take the torch out of the holder

As you can see the torch slides out from the back and the torch wont slide out from the back when the holder is mounted to my chair. So Im thinking if the side of the holder was hinged I could remove the torch that way, but thats way to complicated for me to design, so Im wondering if 1 of you good people could modify the holder for me? I have been using sketchup to design the holder and I can upload you the file if needed

Close up pics and measurements..

As you can see the torch slides out from the back and the torch wont slide out from the back when the holder is mounted to my chair. So Im thinking if the side of the holder was hinged I could remove the torch that way, but thats way to complicated for me to design, so Im wondering if 1 of you good people could modify the holder for me? I have been using sketchup to design the holder and I can upload you the file if needed

Close up pics and measurements..

Last edited:

I will send you them over whatsapp when I have had a look. That print looks good mate.

I will send you them over whatsapp when I have had a look. That print looks good mate.