I dunno, they go to all that trouble to make the fan spin smoothly and what do you go an do?!

BLTouch just arrived. Need to find enough sanity to wrap my head around it all now. Too many plates spinning at once at the moment!

BLTouch just arrived. Need to find enough sanity to wrap my head around it all now. Too many plates spinning at once at the moment!

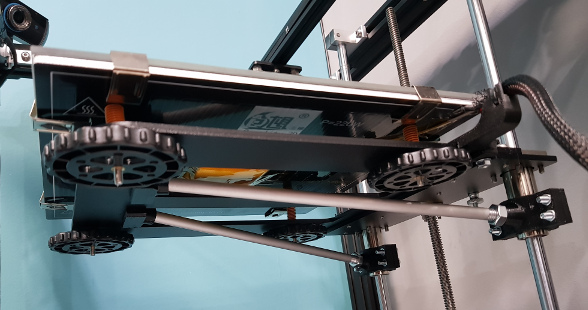

... See top left!

... See top left!