Associate

- Joined

- 19 Oct 2010

- Posts

- 2,081

Let me know when you're selling wheels. I'll buy one if you price reasonably

Hah, reasonable is subjective!

It's always been a problem with this sort of stuff - if you are going to mass produce something it's pretty easy to get things down to a good price and a good margin. Making small batches or one offs is comparatively very time consuming, and of course time is one of the most valuable commodities of all!

For example it's why this base rig itself just isn't viable really as anything other than an endeavour of love, if I assigned even a measly £15 an hour for my time which is ridiculously low it would price itself out of the market. People in general aren't willing to pay for the time required, a problem my friend that makes bespoke furniture encounters regularly - many can't seem to understand why a bespoke wardrobe made by an artisan (him, I'm not referring to myself as an artisan lol) costs more than the one they can get down Ikea with a side of meatballs.

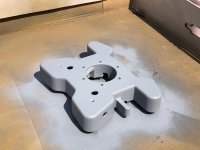

Decided the ABS needed a bit more chutzpah, I've burnt out 2 trying to get sufficient feedback, so after some searching I came across this 40w puck from Dayton Audio... the one it replaces is 25w

I had to make a small mounting adaptor for it as the way it mounts is different, and it's not quite as pretty but hopefully the feedback will be better - will give it a try this eve!

) and enough left over to cover the costs of building 4x actuators for full motion.... exciting times!

) and enough left over to cover the costs of building 4x actuators for full motion.... exciting times!